Prefabricated point foundations

PREFABRICATED POINT FOUNDATIONS FOR SHALLOW FOUNDATIONS

Montažni točkovni temelj je prefabriciran armiranobetonski element, sestavljen iz vezane armature in betona, ki deluje kot opaž pred končnim betoniranjem na gradbišču.

Geometrijske dimenzije in količina jeklene armature so določene na podlagi statičnih izračunov, ki upoštevajo porazdelitev obremenitev notranjih napetosti in nosilnosti tal.

Uporaba montažnih temeljev odpravlja potrebo po opaževanju in armiranju na gradbišču, kar pomeni:

manj delovnih postopkov na terenu,

večjo neodvisnost od vremenskih pogojev,

bistveno skrajšan čas gradnje.

Armatura temelja se prilagodi vsakemu objektu posebej v odvisnosti od obremenitev in terena na katerem objekt stoji.

DIMENSIONS

Montažne točkovne temelje izdelujemo v različnih dimenzijah, da se optimalno prilagodijo vsem konstrukcijskim in statičnim zahtevam posameznega objekta.

The dimensions of the prefabricated point foundation are 2.5 x 2.5 x H, where the height H is adjustable according to the static requirements of the individual construction. Also, the width of the foundation is adjustable by implementing a wider AB base plate, which is connected to a prefabricated point foundation of fixed floor plan dimensions.

ASSEMBLY

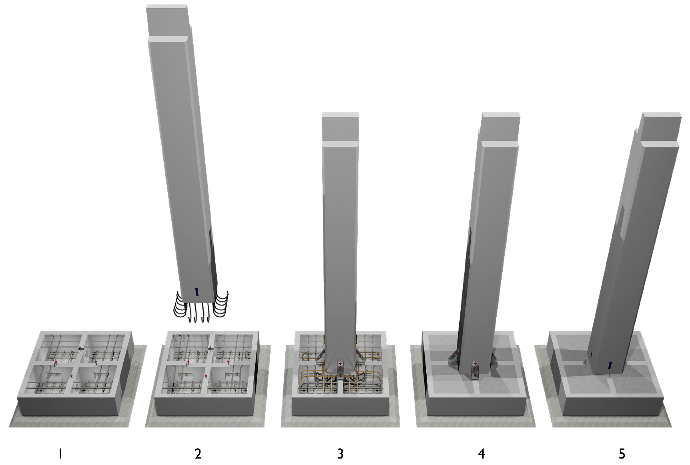

During the assembly process, the precast foundation is placed on the pre-prepared concrete base (1), then the precast column together with the bent rebars is placed on the precast point foundation (2). The upper reinforcing bars are inserted into the foundation and the column is fixed to the foundation with steel plates (3). the foundation is filled with concrete (4). The work is completed by removing all fasteners (5).).

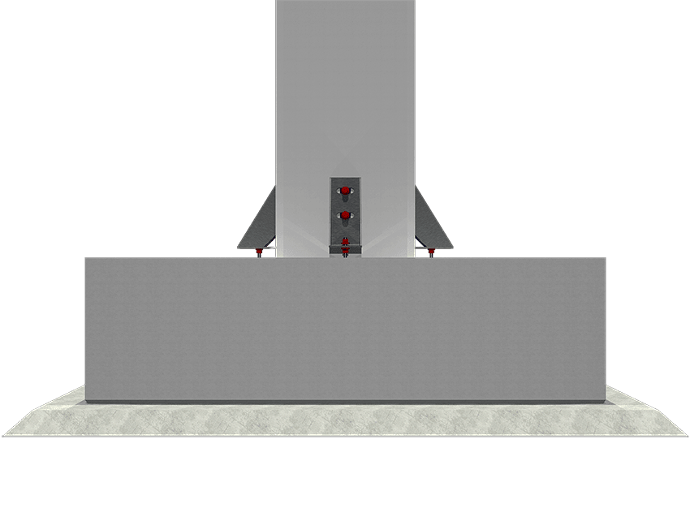

Za natančno postavitev in poravnavo (centriranje) montažnih stebrov se uporabljajo jekleni kotniki, ki omogočajo hitro, enostavno in precizno montažo brez potrebe po dodatnem začasnem podpornem sistemu.

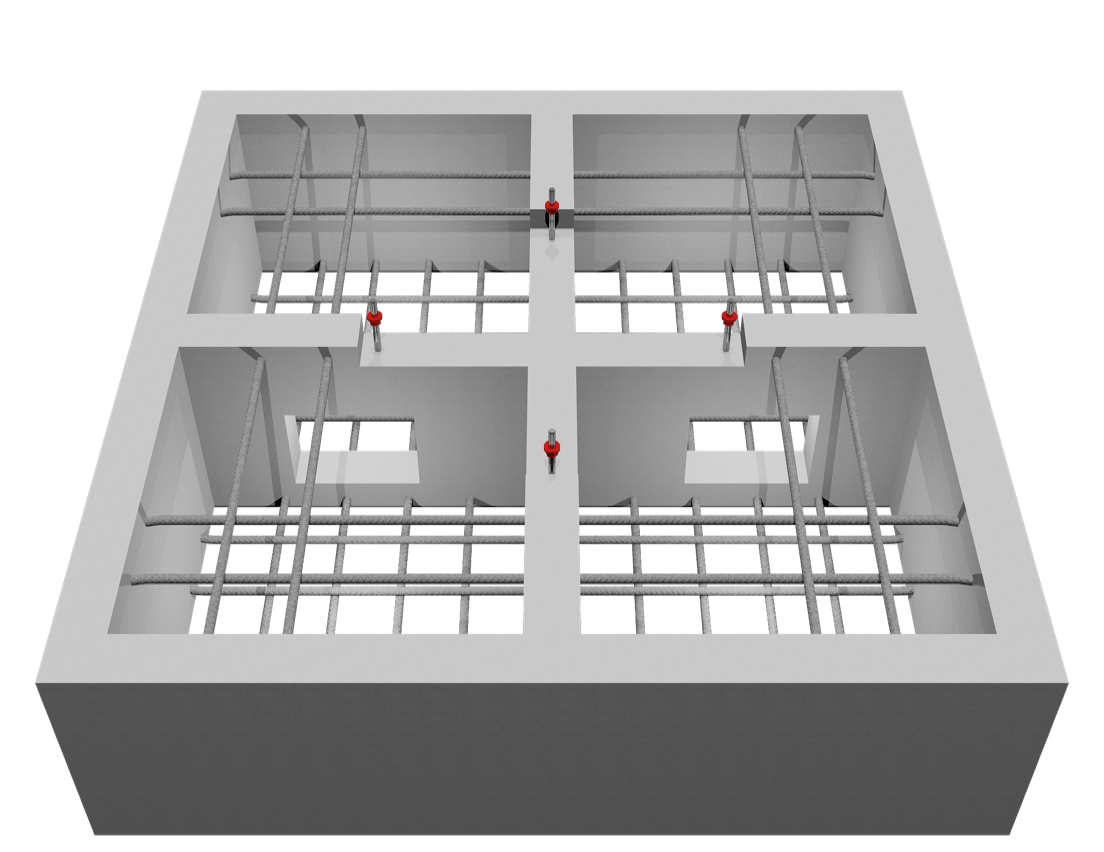

Že v fazi proizvodnje montažnega temelja se v osrednje betonske stene vgrajujejo štiri navojne palice, medtem ko je montažni steber opremljen z osmimi navojnimi spojkami. Povezava med obema elementoma se vzpostavi preko jeklenih kotnikov, sidrnih navojnih palic, kovinskih vložkov in vijakov z maticami.

Ta sistem omogoča natančno pozicioniranje stebra v želeni osi brez dodatnega podpiranja ali zagozditve v temeljno čašo. Z odpravo potrebe po poševnih podporah bistveno poenostavimo montažo, izboljšamo varnost na gradbišču in skrajšamo čas vgradnje.

MAIN ADVANTAGES

glavna nosilna armatura stebra je sidrana neposredno v steber brez prekinitve, s čimer dosežemo najkvalitetnejši stik stebra s temeljem,

- Greater seismic safety.

- precej manjša višina temelja (manj izkopov, betona …),

- We avoid casting and reinforcement on the construction site.

- Possible execution of the foundation on the floor plate.

- hitrejša izvedba,

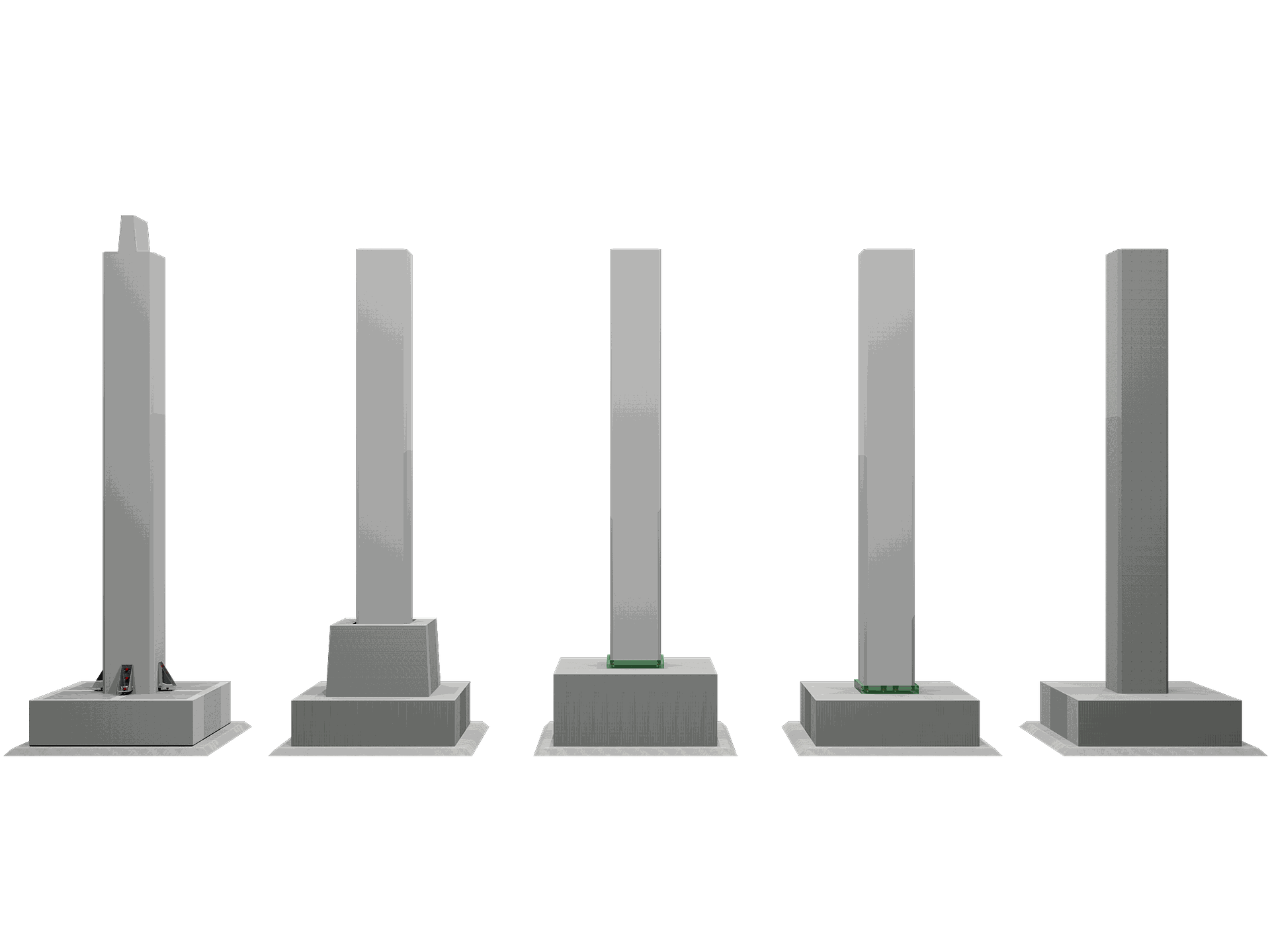

- manjša poraba betona (kot razvidno na sliki levo, kjer so prikazane različne rešitve izvedbe temeljenja stebra).